HOW TO PROPERLY USE AN A/C VACUUM PUMP

It occurred to me that not everyone knows how to use (or even uses) an evacuation or vacuum pump after doing some kind of work on an A/C system. Obviously you could take it to some mechanic shop and have them do it (lame) or buy a vacuum pump like I did and do it yourself. It isn't hard to do just a little tricky.

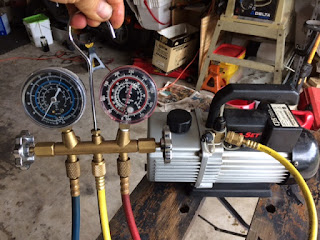

First get yourself a cheap vacuum pump. Here is mine:

|

| single stage vacuum pump you can see the hose ports |

|

| vacuum pump oil level and drain bolt (very necessary) |

In a basic sense, the vacuum pump boils water vapor out of the A/C system that you left open to the air. This leaves no water in the system which can form ice and mess up all kinds of stuff (not to mention the oil which is hydroscopic.......that means it absorbs water.) In order to do this of course you have to have an A/C hose and gauge manifold like the one shown below.

|

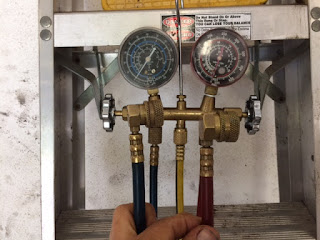

| Here is the A/C manifold gauge with high and low side connectors shown |

The blue is for the low pressure (suction) side of the system and the red is for the high pressure side. Both need to be connected to the system when vacuuming out the system in order to get all the water out. The yellow hose in the middle of the gauge manifold is the one you plug into the vacuum pump. Find the proper connection size (mine had three) and twist it on. Attach the hoses to the ports on your car. Make sure the two handles on the ends are turned all the way to the right (closed) and turn on the vaccum pump. It should run for a couple of minutes before you open the valve handles (left turn) and let it start sucking all the moisture out of the a/c system. On my pump a slight foggy mist comes out of the fill port of the pump as it boils out the moisture. Cool.

|

| The yellow attached to the vacuum pump |

With the gauge cluster attached, the pump running and the handles open, the blue gauge with the smaller numbers will have a part that measures vacuum to the right of 0 on the pressure gauge. As the vacuum pump pulls more and more vacuum the gauge will read a vacuum more towards 30 hg (which is what you want). If for some reason it dosn't move at all, you probably have a sizable leak somewhere and you need to find it in order to close it off. It is usually an o ring or some other fitting so look carefully.

|

| blue gauge at zero, vacuum pump not started |

|

| vacuum pump close to 30 hg vacuum means its working |

Do not be in a hurry to do this because the process takes over an hour anyways so why rush? Put on your favorite music, read a magazine or whatever because you just saved yourself a bundle of cash. And dont loose your cool.